In my last post, you saw me gather a bunch of samples. I have a bunch more since then! Now comes time to test them all, to try figure out my best options.

Josh, our tailoring tutor for this unit, showed me ways to test the fabrics to see if they are suitable or not.

The process goes:

- Give both sides of the fabric a really good stretch, pulling it as far as it will go. If it goes back into it’s original shape, bingo! If not, then it wouldn’t be great to work with. The reason being that it would start to sag and warp out of shape around places like the knees and elbows.

- If it passes that test, then the next one is to give it a really good press (with a piece of buffer fabric, you don’t want it to melt onto the iron.) Soe types of PVC will bubble, and detatch from its bonded layer. This is definitely no good, as you wouldn’t be able to set things like break lines.

- If it presses okay, then try a bunch of different stitches; Top stitching, creating a seam, sewing both right sides and wrong sides together.

- And finally; purposefully rip stitches, and scratch fabric. This is too see how easy it is to damage the fabrics. Easily damaged fabric wouldn’t be a great for a suit thats being worn on stage, and on tour, etc.

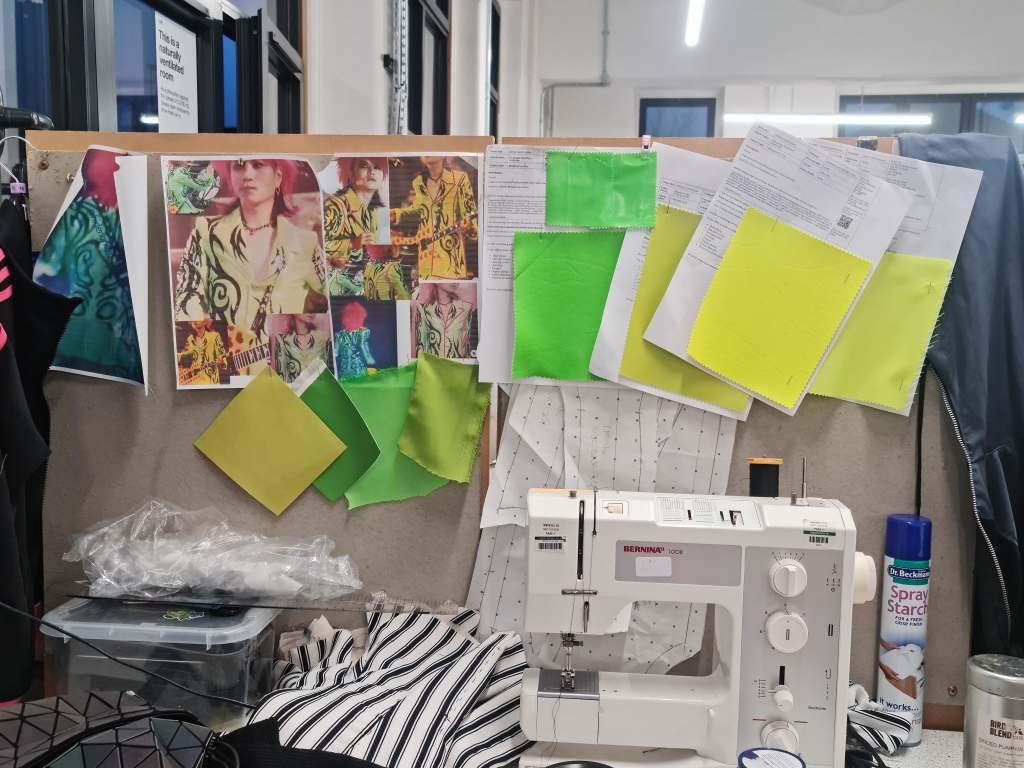

Here is my Desk Of Many Samples. As you can see, I have been really struggling to find perfect fabric. There is a couple of samples here that I do go on to test, and you’ll see those.

My personal favourite is the PVC sample in the upper middle. It looks great under UV lighting, and it is a very similar colour to the suit too. However, it is very thin, and as you’ll see in my sewing samples, not great to sew.

Josh has advised that I stay away from PVC for this project. It is our last unit project, and will become one of the most important in our portfolio, and likely to be on display for our degree show, so it would be wise to choose a fabric that is less stressful to sew.

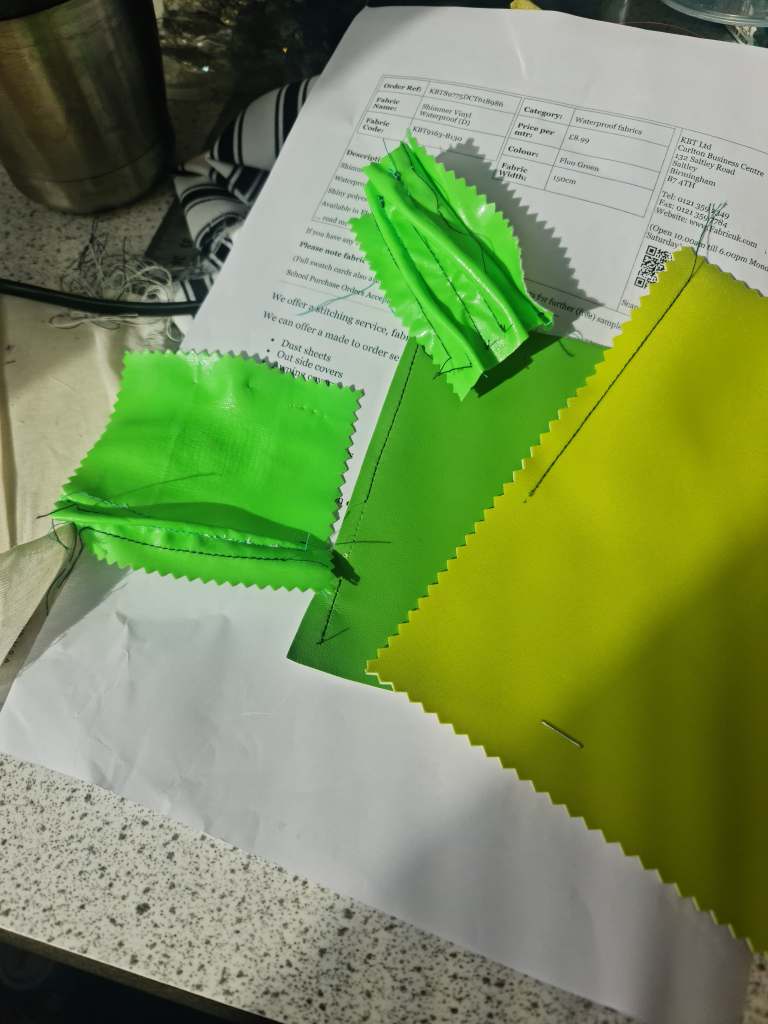

I agree with this, but I am also incredibly stubborn. For now, I have ordered more samples in different fabrics, to see if I can find a good compromise.

From the above – The yellowish scuba sews the best. It also doesn’t mark too badly when you rip stitches out. I don’t like the colour and texture, but it is Josh’s top choice. The middle photo you can see I have ripped a stitch out, and some of the PVC has actually lifted with it. The one on the right is my favourite in colour and texture, but it sews HORRIBLE. It warps, skips stitches, and all sorts. I tried putting some fusible on though, and that makes it much, much better to sew! However, as Josh pointed out, that is a lot of extra work and time to then go ahead and fuse every part of my suit.

All of this testing has basically proven; I need yet more samples. I have ordered a bunch more that I’m waiting to arrive, but in the meantime, here is my trousers drafted up for the test fitting next week! They are a little large on me, as the person I’m making it for is a slightly bigger size, but its looking good so far! The side seam is nice and straight, the darts look good, and the waistband sits straight too. Let’s hope it fits my model next week!

Please excuse the state of my home; renovating a house built in the 1920’s takes a loooong time!

That’s all for this week. Next week will be more details about the fitting, and hopefully I’ll find the final fabric choice!

Leave a comment